Welding Cross Arm / Special Portal Frame

APPLICATION :

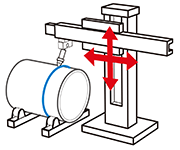

The welding cross arm can work with the welding roller to do automatic workpiece's circumference or inner/outer linear welding such as boiler, Dyeing Machine, Food Tank, Pressure Tank, Pipe, etc...

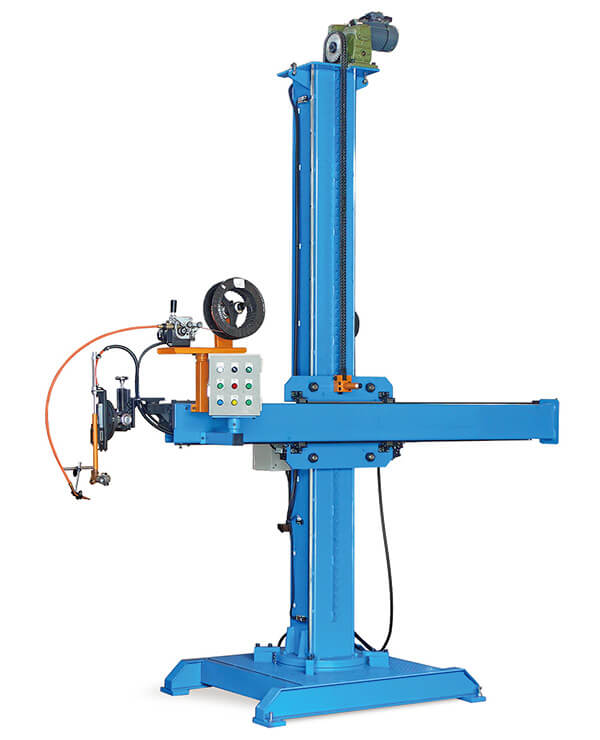

Welding Cross Arm CMTS

Work with the roller to do circumference welding or linear welding and pipe's inner linear welding.

Y axis (vertical arm) can do manual rotation.

The base can work with the moving trolley to move the cross arm.

Heavy-duty chain can increase the lifting safety. The anti-drop gear can prevent chain breaking.

X-axis (horizontal arm) works with D.C. motor for stable movement and is controlled by VR for adjusting the moving speed.

Can work with CO2/MIG, SAW for automatic welding.

Welding Cross Arm

Welding Cross Arm Simple Welding Cross Arm

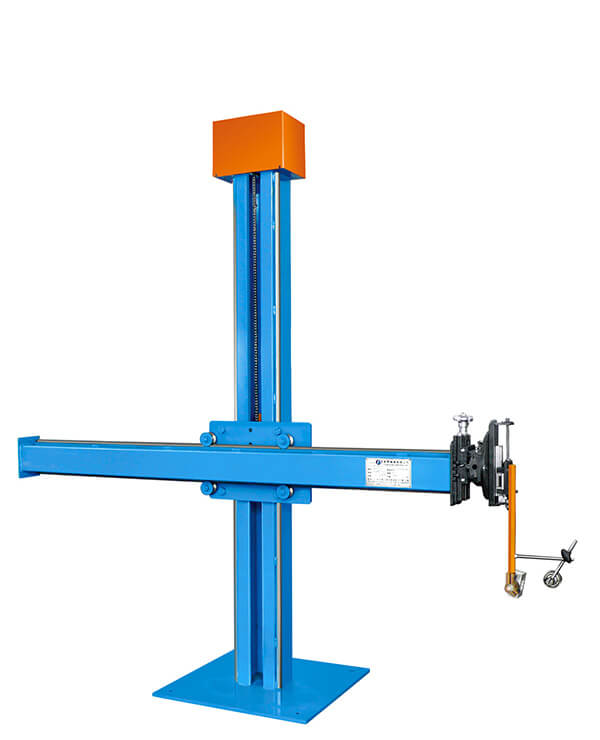

Simple Welding Cross Arm

Welding Cross Arm CMTS

Work with the roller to do circumference welding or linear welding and pipe's inner linear welding.

Y axis (vertical arm) can do manual rotation. The base can work with the moving trolley to make the cross arm move. Heavy-duty chain can increase the lifting safety.

The anti-drop gear can prevent chain breaking.

X axis (horizontal arm) works with D.C. motor for stable movement.

Can work with CO2/MIG and the submerged arc welding.

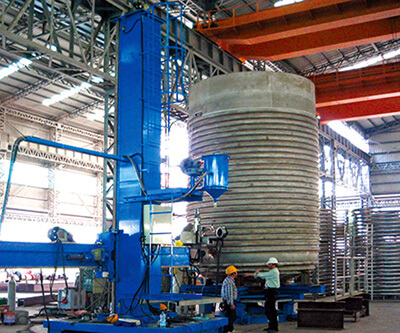

Portal Frame CMTS

Work with the welding roller to do circumference welding or linear welding.

The lifting of the horizontal arm is driven by square thread. High safety & stability.

Working with motor, the horizontal arm's trolley can move stably.

Can work with CO2/MIG, submerged arc welding, TIG + feeding equipment.